Automatic Powder Spraying Line Machine

This machine is specially designed for automatic powder spraying of magnetic material products. Reciprocating online automatic electrostatic powder spraying.

Introduction

- The scope of application of this equipment for spraying: This machine is specially designed for automatic powder spraying of magnetic material products.

- Method: Reciprocating online automatic electrostatic powder spraying.

- Process: work piece -- Product pre-heating hotline (12M) -- Reciprocating automatic electrostatic powder spraying -- Drying and curing line (9.6M) --Turn over -- Product pre-heating hotline (12M) -- Reciprocating powder sprayer -- IR drying and curing line (9.6M) -- Finished product

- Line speed: Speed: 0.6-1.0m/min adjustable, preheating wire, powder spraying machine, curing line.

- Power: Rated power: 130KW

- Equipment area: 32 m *5 m * 3.2 m

Composition

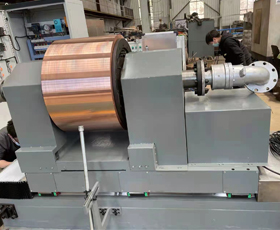

1: Automatic Electrostatic Powder Spraying Machine 1 SET

2: Connecting the Conveyor Line 1 SET

3: Purification and Recovery System 2 SET

4: Automatic Control System 1 SET

5: Baking Lines 2 PIECES

6: Turntable Machine 1 SET (optional)

| Type | Automatic reciprocating electrostatic spraying |

| Usage | Product automatic powder spraying |

| Quantity | 1 set |

| Size | Size:W1320mm×D1600mm×H2000mm |

| ADVANTAGES | 1. The bottom tank is made of T1.5mm 201# stainless steel plate. 2. The cabinet is made of T1.5mm 201# stainless steel plate. 3. Selected 2 sets of automatic electrostatic powder spray guns: SWL-60. 4. Automatic spray gun holder type 2. 5. Number of reciprocating machine axes: X, Z. 6. 2 X-axis motion tracks, upper silver guide rails. 7. 2 Z-axes are for manual adjustment of the gun frame. 8. X-axis movement adopts Japanese Mitsubishi Sifu motor. 9. Two electrostatic spray guns are individually adjustable. 10. Two spraying methods: continuous spraying and induction spraying. 11. 2 vibration plates, adjustable vibration intensity, scale display. 12. vulcanization barrels, adjustable, vulcanization intensity, scale display. 13. 1 transition conveyor line, used to transition the spray booth and connect the preheating wire and curing line. 14. The exhaust duct is made of 1.0mm white iron. |

2: Connecting the Conveyor Line 1 SET

| Type | Plane connection and transportation |

| Usage | Spray section transition |

| Quantity | 1 set |

| Size | Size:W2120mm×D300mm×H750mm |

| ADVANTAGES | 1. The frame is made of T2.0mm 201# stainless steel plate. 2. Equipped with adjustable cup legs. 3. The chain conveyor belt adopts the force bone type, which runs smoothly. Because this section runs through the spray booth, the chain must be cleaned with an air gun after daily use. 4. 6 points double pitch iron steel chain. 5. Equipped with φ12mm round steel rib. 6. Synchronous control with the front-end preheating conveyor line. 7. Laser sensor is installed at the feeding port to intelligently control the spraying mode. 8. Laser abnormality alarm prompt, which can ensure uninterrupted production and no leakage of spray. |

3: Purification and Recovery System 2 SET

| Type | Filtration and recovery |

| Usage | Recycle powder and purify exhaust gas |

| Quantity | 2 set |

| Size | Size:L900mm×W980mm×H1840mm |

| ADVANTAGES | 1. The bottom tank is made of T1.5mm 201# stainless steel plate. 2. The cabinet is made of T1.5mm 201# stainless steel plate. 3. 2 filter recovery cabinets, each equipped with 4 filter elements. 4. The filter element is installed in a chuck type for easy cleaning and maintenance. 5. One centrifugal fan: 5.5KW ;Rated air volume: 8000 cubic meters/hour 6. 8 pulse solenoid valves. 7. Compressed air explosive head 8 sets. 8. The air inlet and outlet adopt movable soft connection. 9. The bottom of the cabinet is equipped with adjustable cup legs. 10. The recycled powder will fall into the lower drawer for easy collection. 11. Equipped with a 100 mesh manual filter screen, the recovered powder can be reused after filtering. 12.Spray cabinet adopts split design. 13. The exhaust pipe after the fan is made of 1.0mm white iron. |

4: Automatic Control System 1 SET

| Type | Programmable PLC control |

| Usage | The control center for the entire line. |

| Quantity | 1 set |

| Mode | English human-machine interface operation. |

ADVANTAGES |

1. English display, humanized interface design and human-machine interface operation 2. The electrical appliances use Delixi products. 3. The intermediate relay is a Japanese Omron product. 4. Switching power supply made in Taiwan. 5. National standard terminal blocks, terminal blocks, number tubes, control wires, etc. 6. Delixi switches, indicator lights, etc. 7. It can write, store and call spraying programs, and provide PLC programs and circuit diagrams. 8. The preheating line and curing line are controlled by PLC. 9. Two cooling fans. 10. The line markings are clear and accurate, and the operation interface is simple and clear. 11. Digital programming, easy to operate. |

5: Baking Lines 2 PIECES

| Type | SSR controls the heating power of the heating tube. |

| Usage | Powder solidification |

| Quantity | 1 set |

| Size | Preheat wire size: L13600mm×W1100mm×H750mm Curing line size: L12800mm×W1100mm×H750mm |

ADVANTAGES |

1. Rack uses 50×50mm square tube, equipped with adjustable cup feet. 2. The conveyor belt uses a force-bone chain and a 6-inch double-pitch chain. 3. The force bone is made of φ12mm round steel. 4. 2HP Songli brand gear reduction motor, equipped with variable frequency stepless speed regulation: 0.5~4m/min. The linear speed of the preheating line and curing line is displayed on the screen. 6. Preheating temperature zone oven cavity: L2400×W860×H160mm; This line has 5 temperature zones. Curing temperature zone oven cavity: L2400×W860×H160mm; This line has 4 temperature zones. 6. The outer wall of the furnace is painted with 1.5mm cold-rolled plate, and the inner wall of the furnace is made of 1.2mm thick stainless steel plate. 7. Digital display automatic constant temperature: Preheating wire design: room temperature ~ 250° intelligent thermostat. Curing line design: room temperature ~ 220° intelligent thermostat. The temperature of the outer wall of the furnace cannot be 10 degrees higher than the indoor temperature, except for the joint parts. 8. Each temperature zone is equipped with a 370W dedicated wind motor and a 7.5-inch wind impeller. The curing line is equipped with one cooling unit: L2000×W860×H160mm. 9. Preheating stainless steel heating tube: 900W/PCS 15PCS/Section temperature zone*5section=75PCS. Curing line stainless steel heating tube: 900W/PCS 12PCS/Section temperature zone*4section=48PCS 10. Heating speed: about 15 minutes from room temperature to 200°. 11. Each section of the furnace cover can be flipped up to facilitate replacement of heating pipes and fans. |

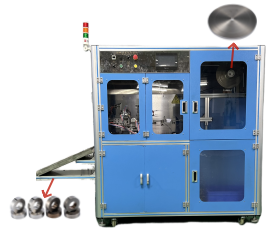

6: Turntable Machine 1 SET (optional)

| Type | Semi-automatic |

| Usage | Magnetic core spray coating turned over. |

| Quantity | 1 set |

| Size | Size:L920*W800*H750mm |

ADVANTAGES |

1. The rack is made of 40*40mm square tube welding. 2. Specifications: L920*W800*H750mm 3. Two linear guide rails, using Shangyin closed guide rails: L920mm 4. Guide rail drive adopts stepper motor. 5. Using PLC and touch screen integrated machine. 6. Holding device 1set 7. 2 sets of pneumatic fingers, height adjustable. 8. The sensor uses a fiber optic amplifier. 9. The sensor uses a fiber optic amplifier 10. Linkage reset between rotary cylinder and linear guide. 11. Reduce workers’ labor intensity. |

Request a Quote