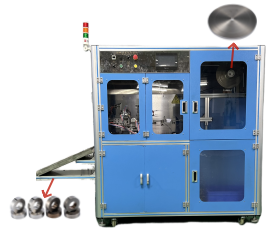

Parylene Coating Machine For Amorphous Core and Nano Core

Parylene Coating is to coat a layer of parylene film on the surface of the workpiece through vacuum vapor deposition (CVD), which is used for waterproofing, moisture-proof, corrosion-proofing and insulation.

Introduction

Parylene Coating is to coat a layer of parylene film on the surface of the workpiece through vacuum vapor deposition (CVD), which is used for waterproofing, moisture-proof, corrosion-proofing and insulation.

The significance of the Parylene Coating Project is to solve the following problems

1.With the continuous development of the information industry, magnetic components are becoming more and more miniaturized. Traditional protection methods such as electroplating or epoxy electroplating paint can no longer achieve reliable protection.

2.It can solve the problem of uneven liquid coating and sharp parts not being able to be coated.

3.Enhance the voltage resistance performance of the product.

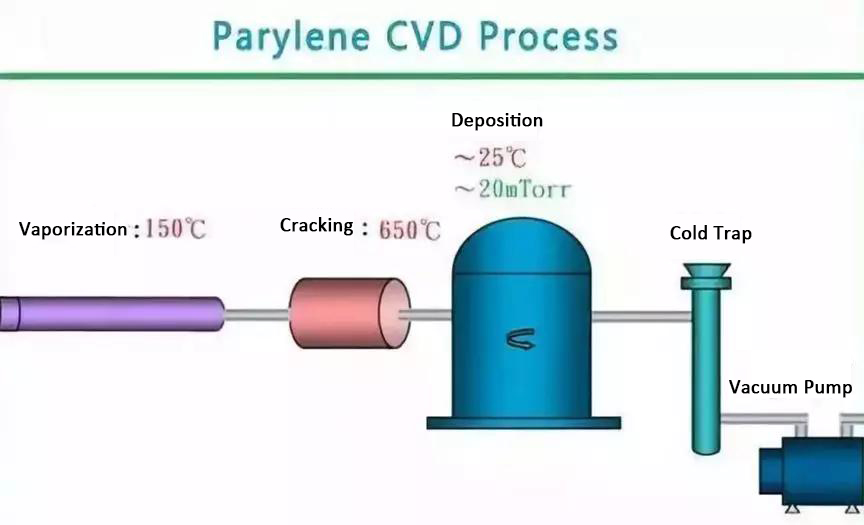

Principle of Parylene coating

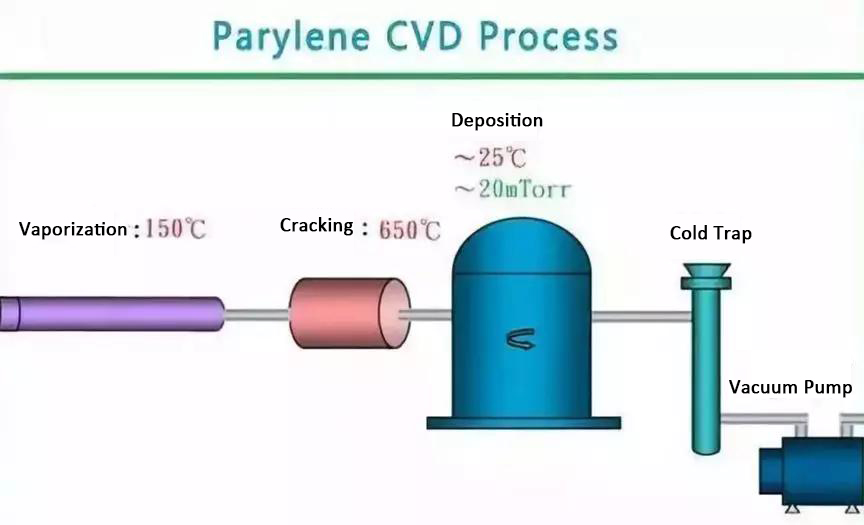

The entire coating process is divided into three steps: monomer vaporization, cracking, and attachment deposition.

1.In a vacuum environment, the solid tetrachloro-p-xylene ring dimer sublimates into a gaseous state at about 150°C in the evaporation furnace.

2.The sublimated dimer gas enters the cracking chamber. At a temperature of about 680°C, the molecular bonds of the dimer are broken, producing active Parylene monomers.

3.At a room temperature (25°C), the free parylene monomer is deposited and polymerized on the surface of the solid substrate to form a pinhole-free conformal film.

The renderings are as follows:

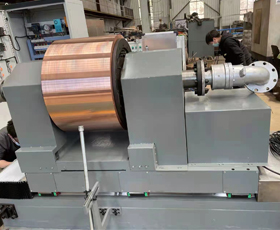

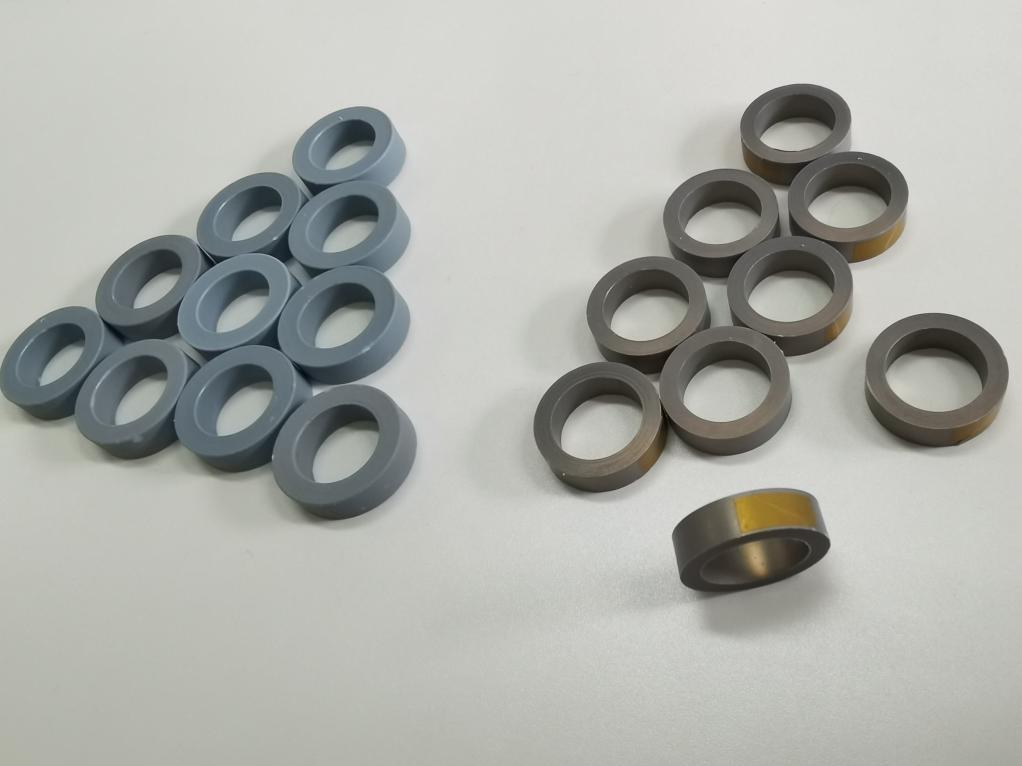

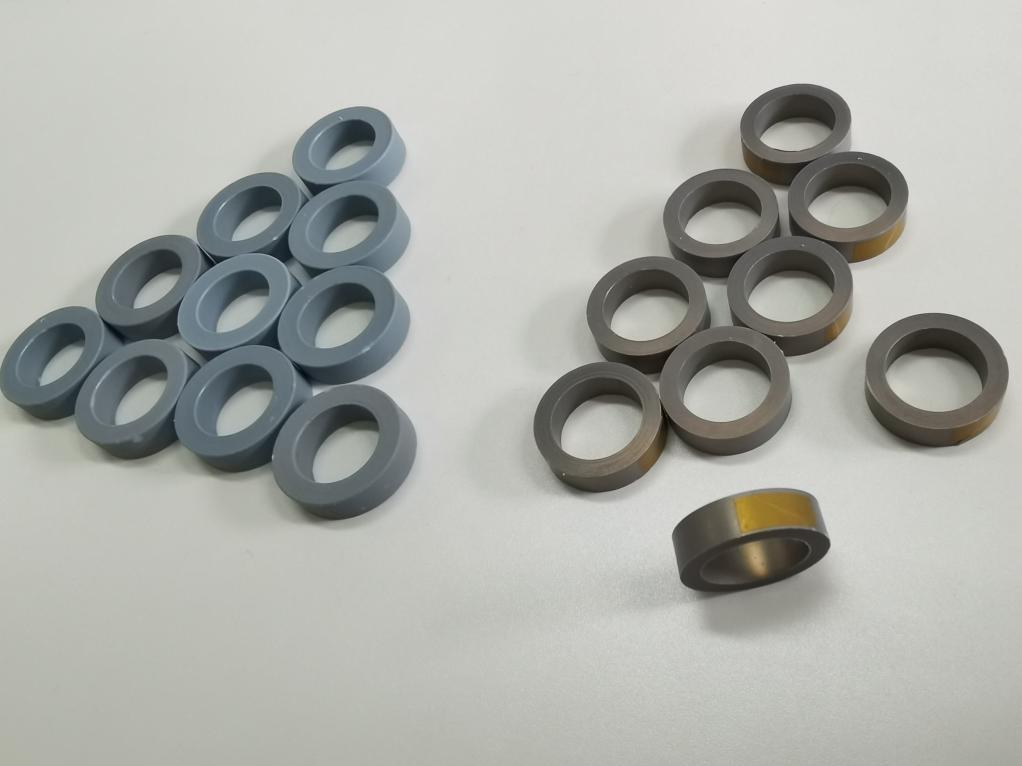

Compare of bare core and epoxy core after Parylene Coating

Application of Parylene coating

Main application areas: magnetic materials, circuit components and components, precision instruments and meters, microelectronic integrated circuits, biomedical treatment, etc.

The significance of the Parylene Coating Project is to solve the following problems

1.With the continuous development of the information industry, magnetic components are becoming more and more miniaturized. Traditional protection methods such as electroplating or epoxy electroplating paint can no longer achieve reliable protection.

2.It can solve the problem of uneven liquid coating and sharp parts not being able to be coated.

3.Enhance the voltage resistance performance of the product.

Principle of Parylene coating

The entire coating process is divided into three steps: monomer vaporization, cracking, and attachment deposition.

1.In a vacuum environment, the solid tetrachloro-p-xylene ring dimer sublimates into a gaseous state at about 150°C in the evaporation furnace.

2.The sublimated dimer gas enters the cracking chamber. At a temperature of about 680°C, the molecular bonds of the dimer are broken, producing active Parylene monomers.

3.At a room temperature (25°C), the free parylene monomer is deposited and polymerized on the surface of the solid substrate to form a pinhole-free conformal film.

The renderings are as follows:

Compare of bare core and epoxy core after Parylene Coating

Application of Parylene coating

Main application areas: magnetic materials, circuit components and components, precision instruments and meters, microelectronic integrated circuits, biomedical treatment, etc.

Request a Quote