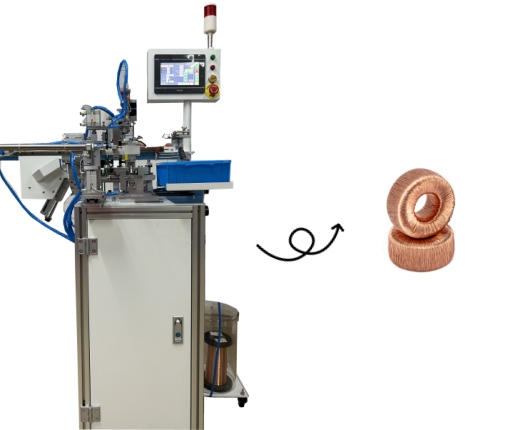

Intelligent Fully Automatic Toroidal Coil Winding Machine

Intelligent fully automatic toroidal coil winding machine adopts PLC human-machine interface control system, with simple and reasonable design and operation, and is suitable for the production of various types of toroidal coils.

Introduction

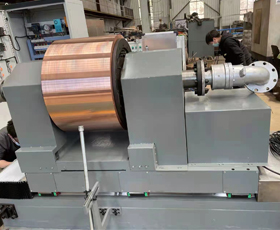

1. You can replace the wire storage ring and guide wheel by yourself according to different product requirements. The equipment adopts a road-mounted design with a simple and compact appearance. With the servo motor, the driving action is smooth, precise and stable. All transmissions and standard parts are from well-known brands, with long life and stable performance.

2. Various winding methods can be customized according to different product requirements (such as: counter-winding, secondary wire storage, etc.)

3. When a fault occurs, the winding machine will automatically stop and alarm, and the alarm item will be displayed on the touch screen.

4. Configure corresponding wire storage rings and corresponding guide wheels according to customer requirements.

5. PLC can store a variety of different winding modes. Each device can adapt to the winding requirements of multiple products. Both storage and winding adopt double pulse recognition and have detection functions.

6. This equipment already has a number of invention patents and utility model patents.

2. Various winding methods can be customized according to different product requirements (such as: counter-winding, secondary wire storage, etc.)

3. When a fault occurs, the winding machine will automatically stop and alarm, and the alarm item will be displayed on the touch screen.

4. Configure corresponding wire storage rings and corresponding guide wheels according to customer requirements.

5. PLC can store a variety of different winding modes. Each device can adapt to the winding requirements of multiple products. Both storage and winding adopt double pulse recognition and have detection functions.

6. This equipment already has a number of invention patents and utility model patents.

Technical Parameter

| Model | |

| Power supply | 220V/110V 50/60HZ |

| Air pressure | 0.6Kpa-0.8Kpa |

| Maximum wire diameter | 0.2mm |

| Minimum wire diameter | 0.05mm |

| Maximum finished outer diameter | 35mm |

| Minimum finished outer diameter | 6mm |

| Maximum finished product height | 20mm |

| Line spacing control | Programming control |

| Sectional winding control | Programming control |

| Cumulative winding control | Programming control |

| Cable motor | Hybrid stepping motor |

| Main motor | Servo motor |

| Winding speed | Adjustable, the fastest equipment is 1400rpm |

| Physical dimension | 1100mm*900mm*1700mm |

| Weight | 72kg |

Request a Quote