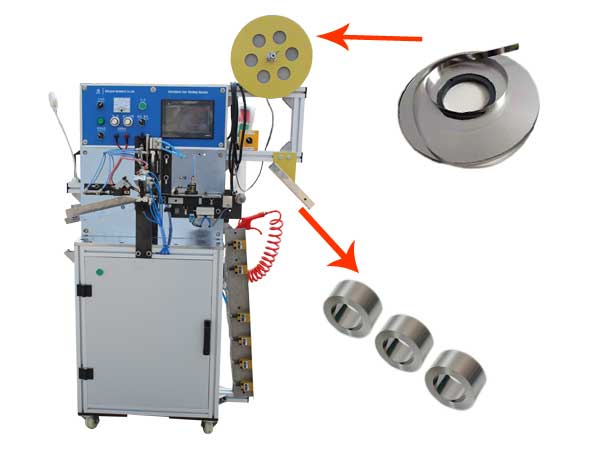

Toroidal Core Winding Machine

Introduction

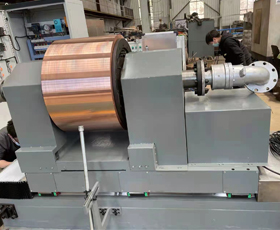

Automatic amorphous core winding machine is one of our main product, the principle is that the servo motor directly contributing to the rolled needle through the gear drive, which is more accurate, reliable and efficient than the traditional machine.

Main Description

Automatic amorphous core winding machine is one of our main product, the principle is that the servo motor directly contributing to the rolled needle through the gear drive, which is more accurate, reliable and efficient than the traditional machine. Thereby, ensuring that the amorphous strip dimensions keeps up with number of turns, which could improve the quality of the toroidal core.

The output of the production could reach 10-20 pcs/ min, it is more fast 3 times than manual work, and the rate of qualified products can reach 99.5%. At the same time, a workman can operate five or six machines, it greatly reduces the production management expenses and the product costs. Automatic alloy amorphous core winding machine is the best choice for the production of amorphous strip toroidal core and ultra- crystal strip toroidal core.

The winding, cutting, welding of inner and outer rings are done automatically, it uses the fixed size to produce. We are committed to promoting the amorphous strip toroidal core, ultra-crystal strip toroidal core.

Main characters

1.Unidirectional winding, automatic cut off, automatic welded

2.Strip with continuous feeding, tension adjustable.

3.The trough using oriented feeding , easy to adjust the width of the range

4.Winding number according to the parameter settings

5.The thickness of the toroidal core is adjustable

6.The strip speed can be adjustable

7.Inner and outer toroidal core is automatic welding

8.The winding speed can be adjustable

9.Using the starting components to operate, easy to maintain

Technical Parameter

Main technical parameters

|

Item |

Parameter |

| Strip width |

3-25mm |

| Inner diameter |

Φ4-40mm |

|

Outer diameter |

Φ5-56mm |

|

Voltage and frequency |

220V-50Hz |

|

Power |

0.6kw |

|

Pressure |

0.4Mpa |

| Size |

1250*850*1650 mm |

| Weight |

150kg |

Request a Quote